When camping, I frequently would like to know the temperature outside our 2020 T@B 320S Boondock Edge trailer as well as inside. I purchased a “ThermoPro TP60S Digital Hygrometer Indoor Outdoor Thermometer” through Amazon (if you purchase from this link I’ll earn a small commission at no additional cost to you) and mounted the indoor module on the wall next to the Alde control panel using Velcro.

Now, where to locate the outside sensor? I placed it in the propane tank / battery box, just setting it on the bottom. This seemed to work fine. The outside temperature seems to be relatively accurate except when the sun is shining directly on the box. The only problem I could see was that the sensor picked up a lot of dirt, and occasionally some moisture from sitting on the bottom. I was also concerned about dropping something on it and damaging the unit.

I have finally gotten around to moving the sensor to a safer location. I figured I could mount it over the flange at the back of the propane tank / battery box and it would be safely out of the way. When the lid is closed, there is a small gap below the lid where the mount can sit without interfering with the lid closing. Using Fusion 360, I designed a holder for the sensor.

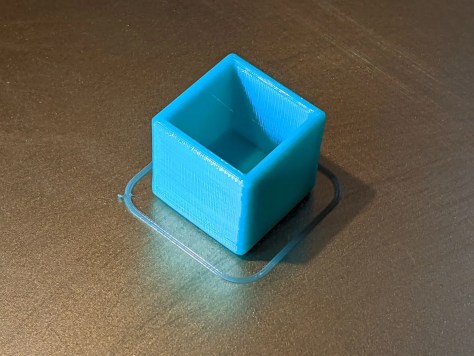

I first measured the width of the flange at the top of the box, and eyeballed how I thought I would like the mount to sit on that flange. I measured the sensor, and made a rough drawing of what I wanted. Then I created a test part in Fustion 360. I just made the end of the sensor mount and about 10mm of the body. That way I could print it in a reasonable amount of time without using too much plastic filament to test the fit. Here’s my first iteration:

I then tested this, and found that it didn’t hang the way I had hoped. It needed something to keep it from tilting.

So, on to iteration #2. I added a little leg to keep it from tilting.

This worked fine. Now that I had tested the hanger, and believed it to be correct, I added the rest of the structure in Fusion 360, and added holes in the bottom to improve air flow to the sensor, resulting in the completed sensor holder.

Available on Thingiverse at www.thingiverse.com/thing:4917124.